Engineered Fabrics

ENGINEERED FABRICS

High-performance technical textiles

MEHLER’s engineered fabrics cover the whole spectrum of woven technical fabrics.

Our fabric solutions are based on industry-proven yarns, engineered fabric constructions, tailor-made fabric finishing, treatments and coatings as well as individual fabric dimensions.

The product portfolio of MEHLER’s technical fabrics is extremely diverse. The products are used in a wide variety of applications. Most of the fabrics are tailor-made to meet the needs of specific downstream processes and end-uses.

Engineered fabrics are often used to reinforce Mechanical Rubber Goods (MRG) In a textile/rubber composite structure, the textile fabric offers the required properties such as tensile strength and rigidity. Only the use of the fabric enables a long durability of the end product. In order to achieve the required degree of adhesion between the textile and rubber, we treat our fabrics with RFL (resorcinol formaldehyde latex), or alternatively, with our RF-free solution Mehler Sustain Adhesive (MSA). Other end applications, in turn, require other types of finishings.

MEHLER’s customers expect highest product quality and on-time manufacturing of our woven engineered fabrics. To meet these requirements, multi-stage processes such as texturizing, twisting, warping, weaving, treating or coating, tumbling, cutting and lab testing need to be managed. We are optimally positioned for such tasks, as we control and manage the entire value chain internally.

Explore our two categories of woven engineered fabrics:

SPECIALTY FABRICS

Specialty Fabrics are woven fabrics with high technical functionality in terms of tensile strength, elongation, weight, thickness and different finishing options. The variety of specialty fabrics is enormous. The technical scope can differ from very light and flexible textiles to heavy and ultra-high tensile strenghts – always depanding on the type of application and its specific requirements.

In order to achieve certain product properties, the woven textiles are further treated. On the one hand, there are so-called dry finishes such as heat-setting, tumbling, calendering and doubling. On the other hand, there is further treatment with wet finishes to achieve the following properties: rubber-friendly, oil/water-repellent, bitumen-friendly, flame/heat-resistant, antistatic, UV-resistant and the optical coloring of fabrics.

Fabric coatings include coatings with PVC dispersion and paste (polyvinyl chloride), NBR (nitrile butadiene rubber), CR (chloroprene rubber), SBR latex (styrene butadiene rubber), PVA (polyvinyl alcohol), PVAC (polyvinyl acetate), PU (polyurethane), silicone and acrylate mixtures.

We produce untreated fabrics with a width of up to 5,40 cm (212″), dip-coated fabrics up to 5,20 m (204″) and treated fabrics up to 2,95 m (116″).

Specialty Fabrics are used in versatile markets and applications like filters, hoses, handrails, ballistic protection vests, flat roofs, awnings, swimming pools, scrims, meshes, geotextiles and many more. In the mobility sector, specialty fabrics are used in timing belts, brake diaphragms, air bag covers, battery covers for electric cars, air filters or composites reinfoced with fabrics like for car interior as dashboards, car bodies or seat frames.

The range of applications is multiplex and not restricted. MEHLER’s scope of applications of Specialty Fabrics is growing steadily – thanks to close cooperations with new customers and with our existing customers on new products. If you are looking for a competent partner for your woven fabric needs – MEHLER is your experienced partner.

For detailed technical information, take a look at our datasheets:

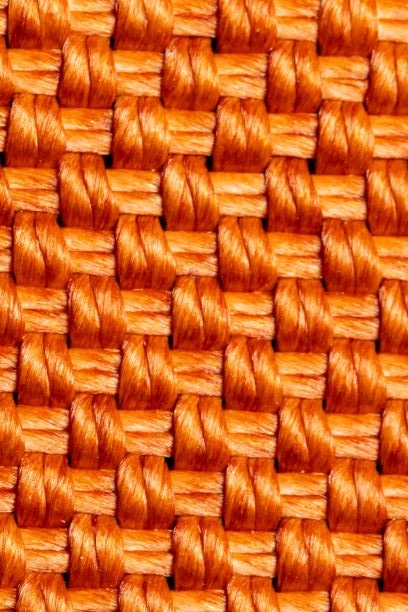

Treated Polyamide Fabric

Warp Construction: dtex 9405×5, polyamide

Weft Construction: dtex 9405×5, polyamide

Weight: 930g/m²

Treatment: RFL

Application: Offshore pipes

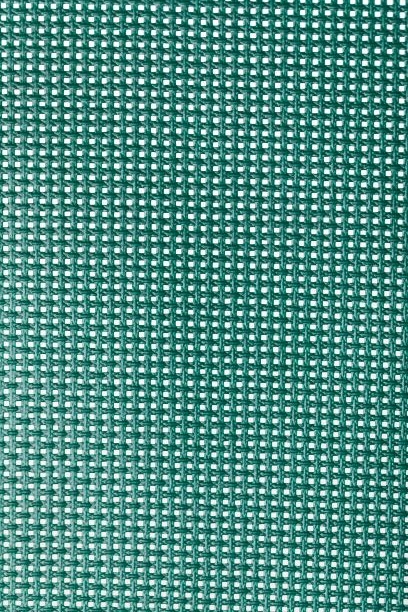

Coated Polyester Fabric

Warp Construction: PET high-tenacity, dtex 1100×1

Weft Construction: PET high-tenacity, dtex 1100×1

Weight: 390 g/m²

Treatment: PVC coating, green

Application: Shading – awnings, canopies

Liner Fabric

Warp Construction: Spun Polyester, Nm 40-2

Weft Construction: Spun Polyester, Nm 34-1

Weight: 310 g/m²

Treatment: rubber-repellent

Application: auxiliary material – liner fabric

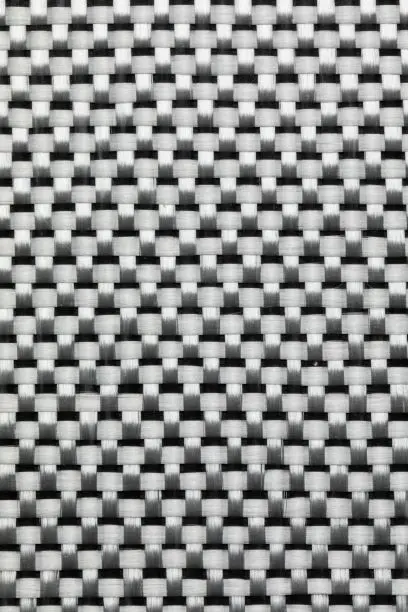

Glass Fabric for Composites

Warp Construction: dtex 3000, glass roving

Weft Construction: dtex 3000, glass roving

Weight: 290g/m²

Treatment: untreated

Application: Car interior composites – car bodx, dashboard, seat frames

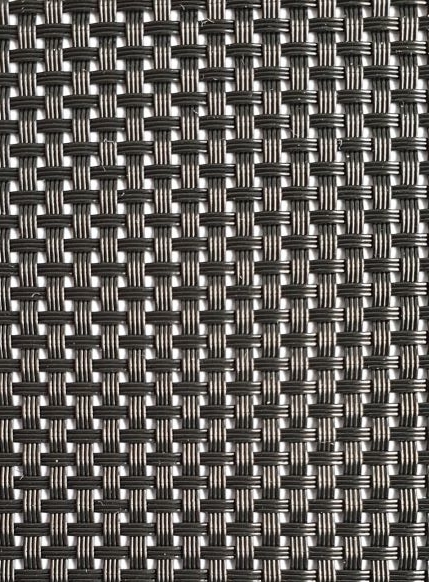

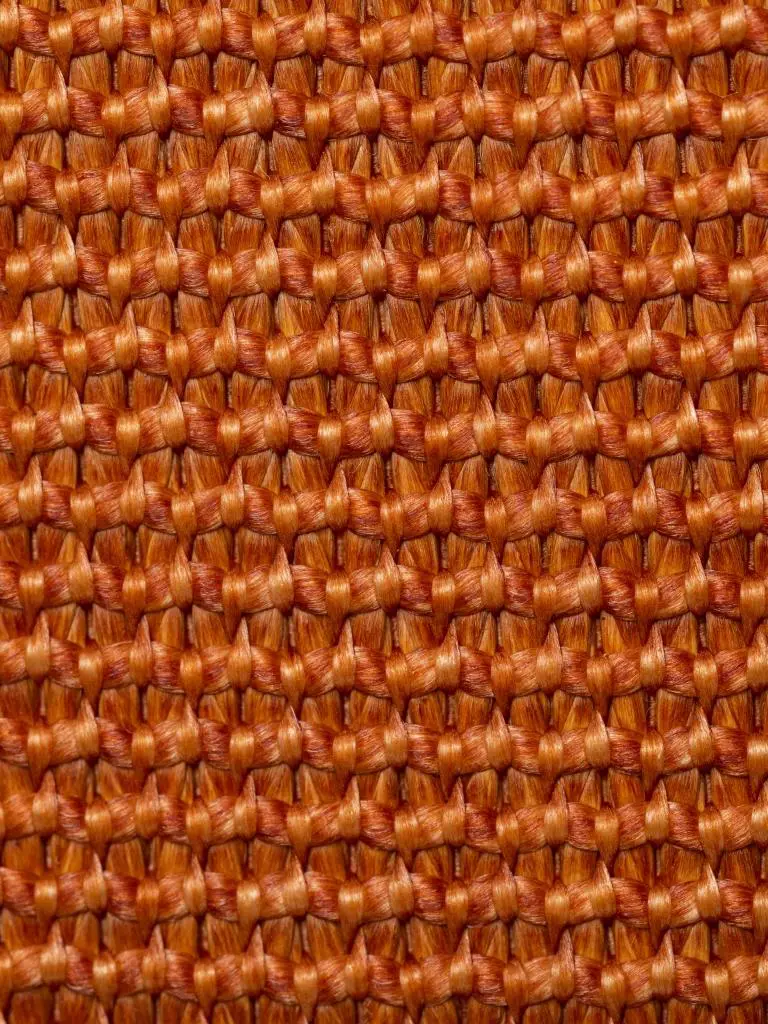

PP Monofil Fabric

Warp Construction: dtex 910, PP Monofil black

Weft Construction: dtex 910, PP Monofil black

Weight: 310g/m²

Treatment: untreated

Application: Trampolines

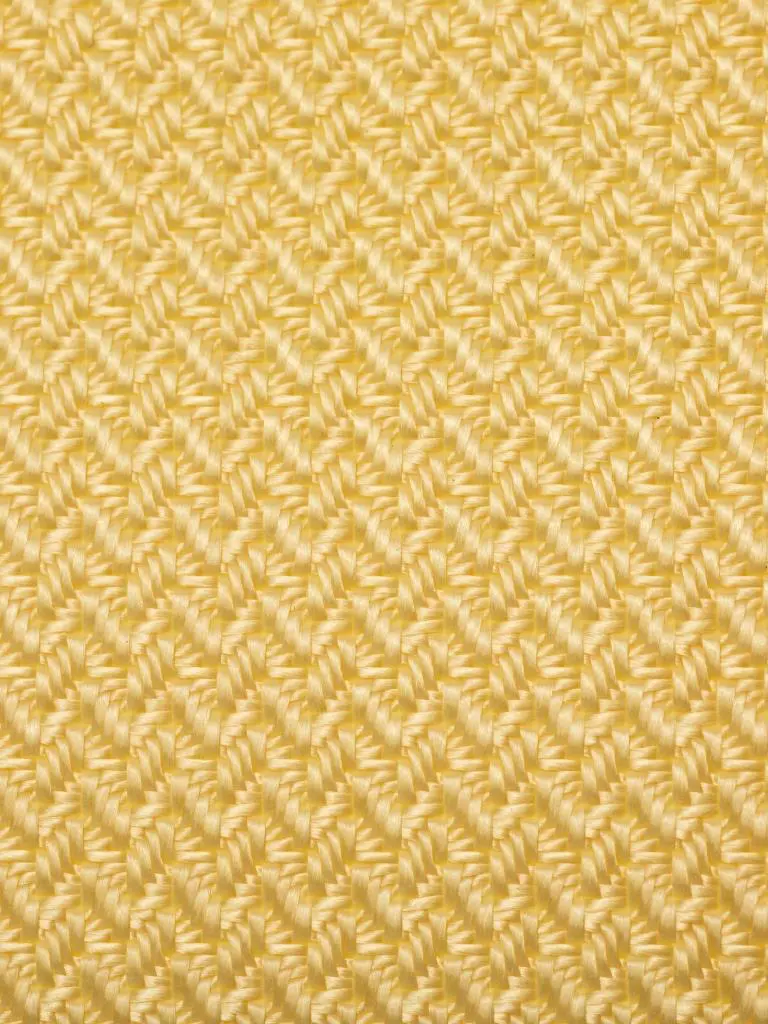

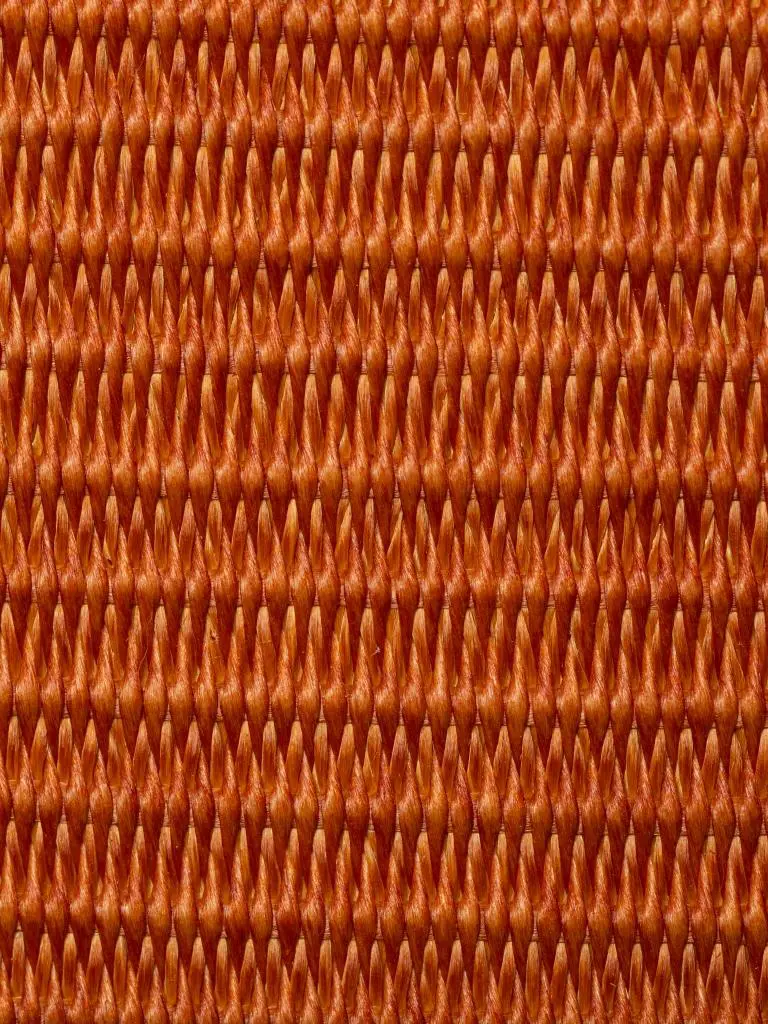

Polyamide Stretch Fabric

Warp Construction: dtex 235×1, Polyamide texturized

Weft Construction: dtex 110×2, Polyamide texturized

Weight: 270 g/m²

Treatment: Tumbling + RFL

Application: Timing Belts

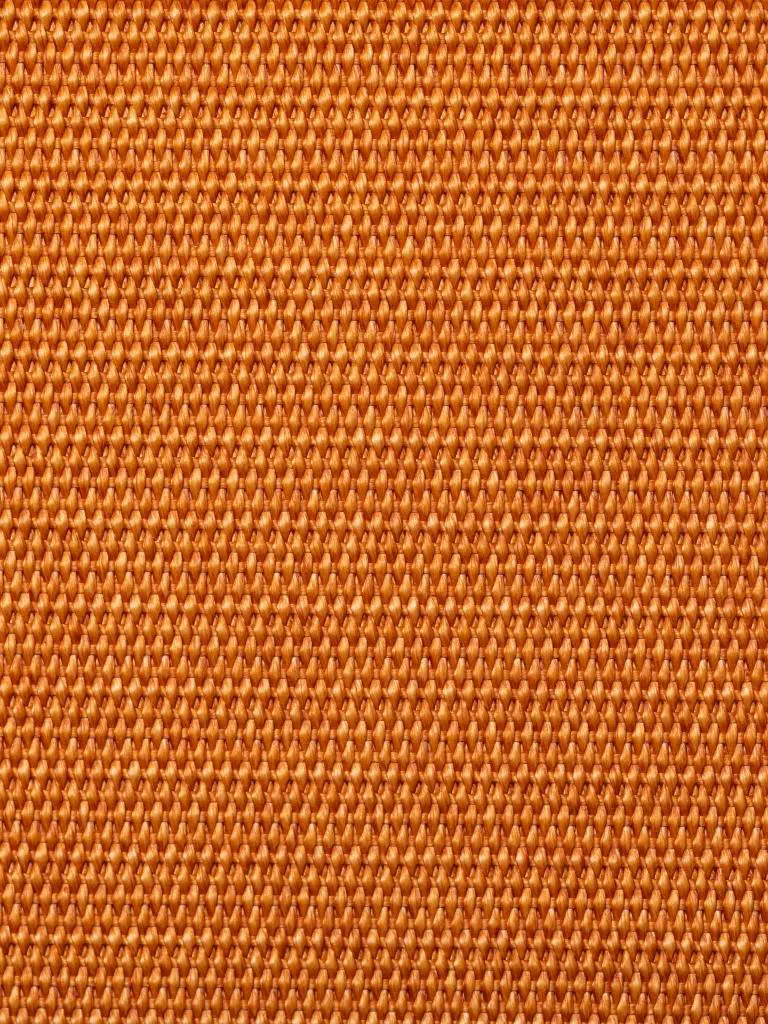

Polyester Base Fabric

Warp Construction: PET high tenacity, dtex 1100×1

Weft Construction: PET high tenacity, dtex 1100×1

Weight: 260 g/m²

Treatment: untreated

Application: Base fabric for industrial coating applications, e.g. inflatable boats

Vectran Base Fabric

Warp Construction: Vectran, dtex 1670×1

Weft Construction: Vectran, dtex 1670×1

Weight: 610 g/m²

Treatment: untreated

Application: Base fabric for industrial coating applications, e.g. airships

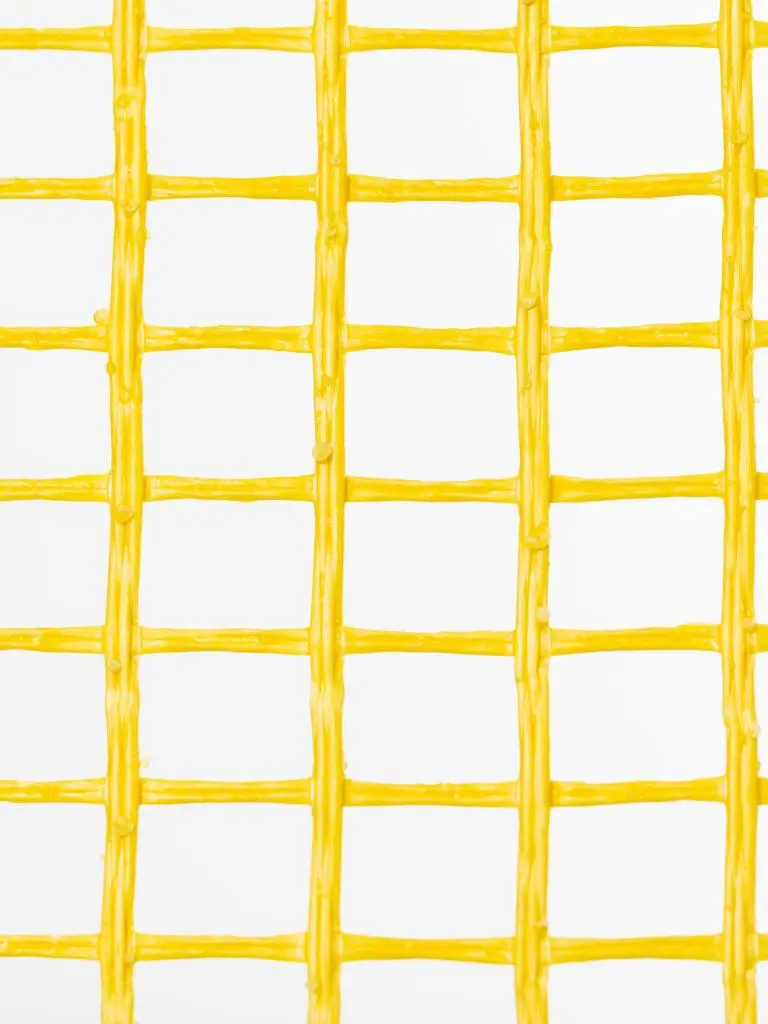

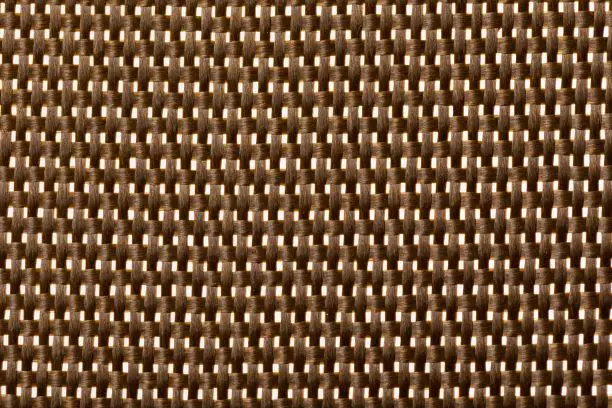

Aramid Grid Fabric

Warp Construction: Aramid, dtex 3360×1

Weft Construction: Aramid, dtex 3360×1

Weight: 200 g/m²

Treatment: SBR Rubber

Application: Plaster Reinforcement

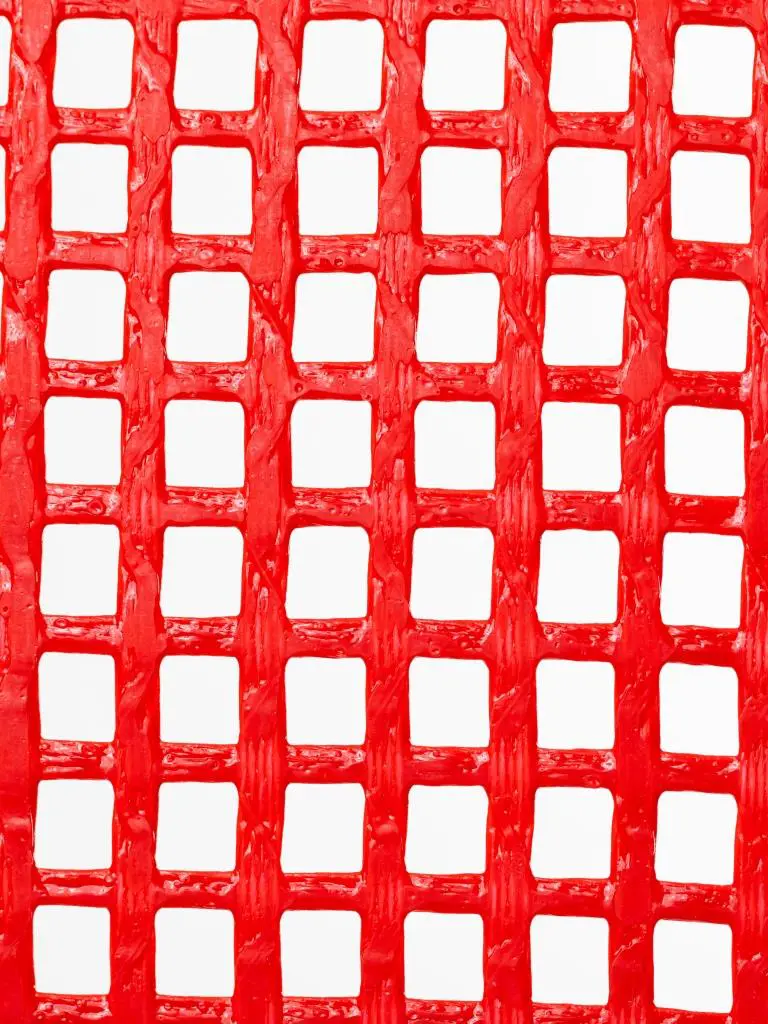

Polyester Grid Fabric

Warp Construction: Polyester high tenacity, dtex 3380

Weft Construction: Polyester high tenacity, dtex 3380

Weight: 870g/m²

Treatment: PVC

Application: Snow & safety fences

CONVEYOR BELT FABRICS

MEHLER is a global leader when it comes to the comprehensive range of converyor belt fabrics. Conveyor belts have to transport light to ultra-heavy bulk material, depending on the field of application, and thus have to fulfill specific requirements. With our technologies and long-lasting experience, we can offer endless options and provide the fabric solution which is needed. We produce high-end conveyor belt fabrics including a wide range of high-quality finishes like rubber-friendly (SBR, NBR, CR, …), rubber repellent, flame/fire retardant and many more customized treatments on request.

Conveyor Belt Fabrics are used in mining, industrial and agricultural applications.

Our product portfolio of conveyor belt fabrics comprises:

EP | PN fabrics with Polyester in warp and Polyamide 6.6 in weft

EE | PP fabrics with Polyester in warp and weft

PP | NN fabrics with Polyamide 6.6 in warp and weft

Straight Warp fabrics with Polyester and Polyamide 6.6 in warp and Polyamide 6.6 in weft

Aramid Straight Warp fabrics with Aramid and Polyamide 6.6 in warp and Polyamide 6.6 in weft (for extremely heavy-duty applications and as efficient alternative to steel-cord belts)

Aramid fabrics

Breaker fabrics (serve as safety layer to prevent damages of the carcass of the belt, to minimize serious belt defects)

Basalt fabrics (high fire-resistant properties)

Auxiliary fabrics (liner fabrics, impression fabrics)

Possible fabric widths are between 60 cm (23,6″) and 290 cm (114,2″) for treated and 335 cm (132″) for greige conveyor belt fabrics.

For detailed technical information, take a look at our datasheets:

Explore some conveyor belt fabric constructions below:

Basalt Fabric

Warp Construction: dtex 940×3

Weft Construction: dtex 940×3

Weight: 410 g/m²

Treatment: RFL

Application: fire & heat resistant applications

DPP 630 Straight Warp-VS

Straight Warp Construction: Aramid

Binding Warp Construction: Polyamide

Weft Construction: Polyamide

Weight: 1085g/m²

Treatment: RFL

DPP 1250 Straight Warp - VS

Straight Warp Construction: Aramid

Binding Warp Construction: Polyamide

Weft Construction: Polyamide

Weight: 1665g/m²

Treatment: RFL

DPP 1400 Straight Warp - VS

Straight Warp Construction: Aramid

Binding Warp Construction: Polyamide

Weft Construction: Polyamide

Weight: 1630g/m²

Treatment: RFL

EpP 630 Double Weave

Warp Construction: Polyester + Polyamide

Weft Construction: Polyamide

Weight: 1980g/m²

Treatment: RFL

EpP 315 Double Weave

Warp Construction: Polyester + Polyamide

Weft Construction: Polyamide

Weight: 1160g/m²

Treatment: RFL