Innovation

… makes the difference between a leader and a follower. (Steve Jobs)

INNOVATION

powered by Mehler

INNOVATION NETWORK & DEVELOPMENT PROCESS

Our innovation process is structured as an end-to-end process. It starts and ends with our customer. The innovation power of MEHLER and its innovation network is strong and clearly structured. In addition to intense cooperation with our customers, we develop innovative solutions together with institutes, universities and selected partner companies and suppliers.

Our technical experts work closely together with our clients. The customers receive continuous feedback on all key stages of the development process and get complete transparency in the project plan. We define warning signals, thus recognize critical situations at short notice always keep an eye on the time defined ‘time-to-market’. After the product has been launched on the market, we will continue to be in regular contact with our customers and closely coordinate any desired production optimizations.

Our two R&D centers are located in our headquarters in Fulda / Germany and in our production plant in Famalicão / Portugal.

You are currently viewing a placeholder content from Youtube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

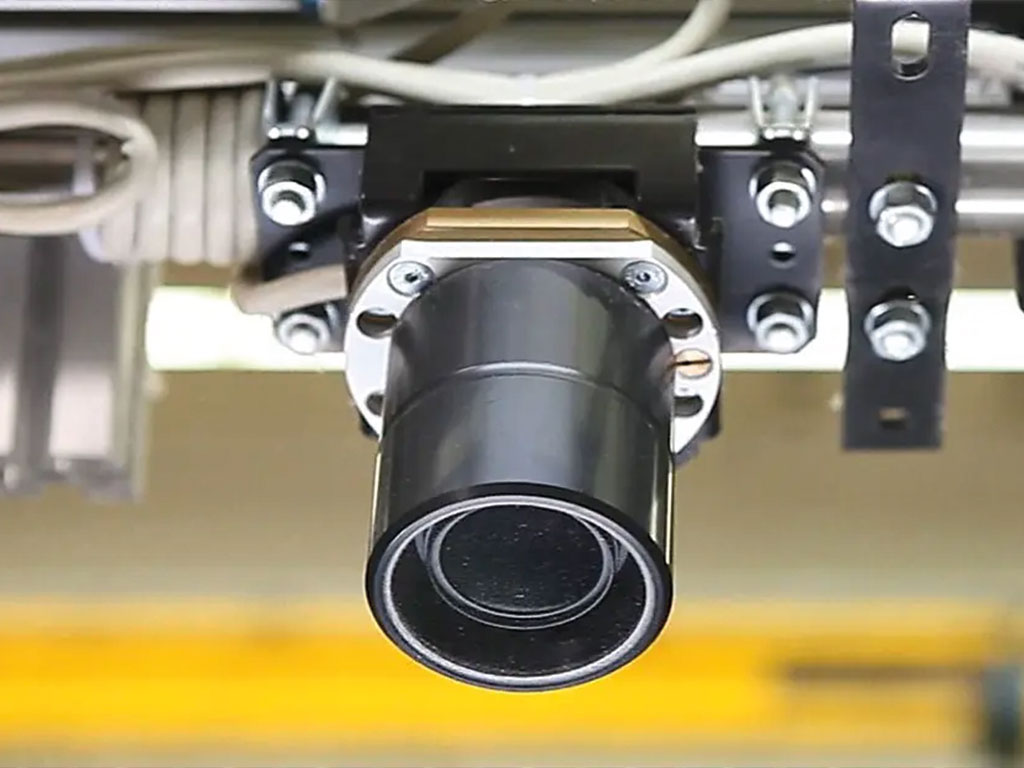

More InformationRF-free treatment solution

Our experts developed a sustainable, RF-free and CO²-neutral treatment for Mechanical Rubber Goods (MRG) reinforced by technical textiles. The innovative treatment solution MehlerSustainAdhesive – MSA – consists of natural components and contributes to a responsible treatment of the environment, people and our future. Learn more about it by taking a look at our video: (available in English only):

BasaTexx FP

Fireproof Membranes

BasaTexx FP is an innovative, high-performance technical fabric made of Basalt and treated with a fire-resistant coating. Through the interaction of the mineral fiber material with a special elastomer coating, a non-combustible, flexible, and lightweight tarpaulin or composite material was created.

The new developed fabric can be used for multifunctional applications and system solutions. Wherever high fire protection requirements are necessary and the general fire load has to be reduced, BasaTexx FP is the perfect lightweight material solution. The fabric meets the requirements of building material class A2-s1,d0 according to DIN 4102-1 and EN 13501-1 (equals to ISO 1182).

BasaTexx FP is characterized by a high flame retardancy and temperature resistance (up to 1.200 °C / 2,200 °F); high tensile and compressive strengths; UV-, chemical and corrosion resistance and no melting and dripping behaviour when exposed to fire.

Scroll down for more details and take a look at our detailed BasaTexxFP Product Sheet.

Fire shaft burntest

Fire shaft burntest proofs the non-flammable properties of BasaTexx FP (picture: after 6 minutes of exposure to fire).

Application example: Aviation

Air cargo container with lightweight, non-flammable BasaTexx FP fabric cover.

Application example: Construction

Fireproof partition curtain with BasaTexx FP fabric in a sports hall.

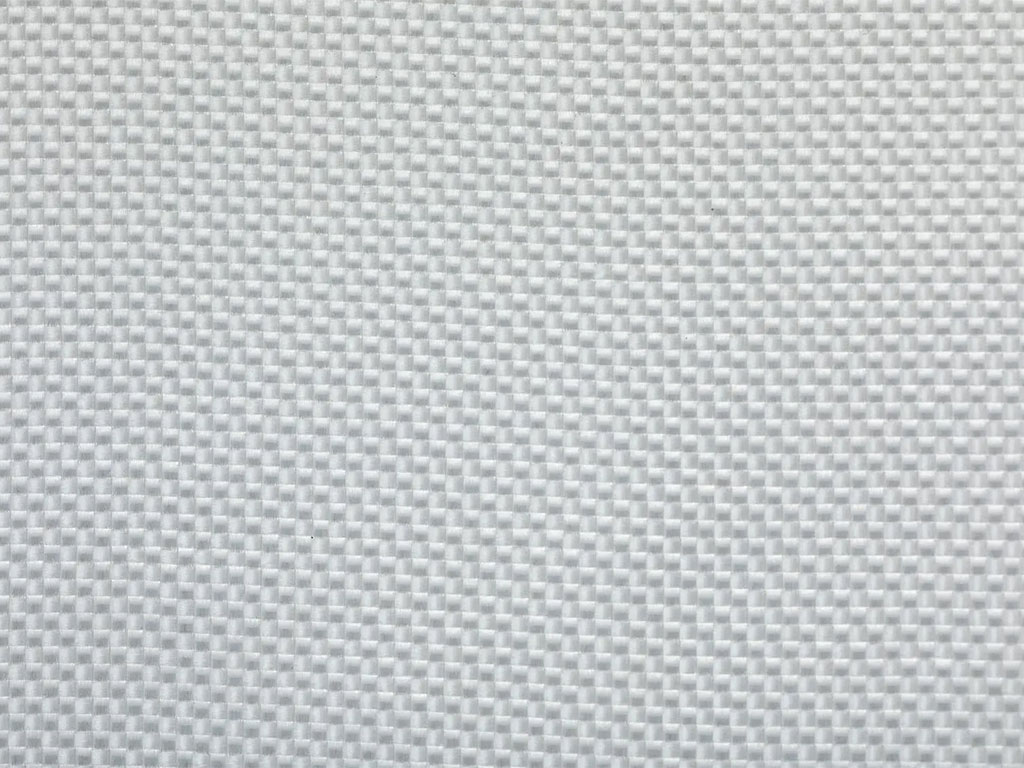

BasaTexx FP

BasaTexx FP fabric roll with a white elastomer coating.

Individual coating possibilities

Individual coating possibilities

BasaTexx FP fabric with a yellow fireproof elastomer coating – coatings in individual colors possible.

Interested in BasaTexx FP or MSA? Contact our experts:

- Mine Frieß

Global Sales Director

Specialty Fabrics

Applications:

airsprings, tracks, hoses, geotextiles, roofing, flooring, shading & others

Phone: +49 661 103 574

E-mail: mine.friess@mehler-ep.com

- Petra Schröder

Sales Manager

Specialty Fabrics

Applications:

geotextiles, flooring, roofing, shading & others

Phone: +49 7741 8078054

E-mail: petra.schroeder@mehler-ep.com

- Katharina Falkenstein

Sales Manager

Specialty Fabrics

Applications:

airsprings, tires, tracks, hoses, geotextiles, roofing, flooring, shading & others

Phone: +49 661 103 313

E-mail: katharina.falkenstein@mehler-ep.com

MEHLER IS

shapes the future

With our knowledge and experience, we contribute to transfer ideas into value-added solutions for the benefit of our customers.

Lightweight

Textiles

Fire- and Heat-resistant Textiles

High-Performance Materials

Hybrids

Ribbon fabrics

Grid and Scrim Fabrics

RF-free Adhesives

Multilayer fabrics

Wire mesh